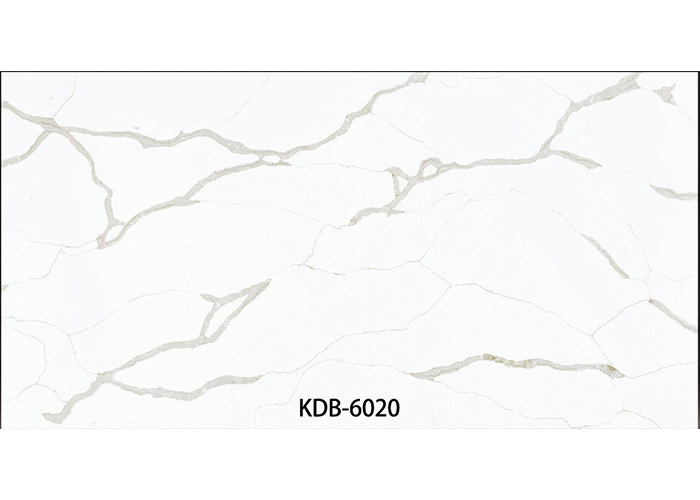

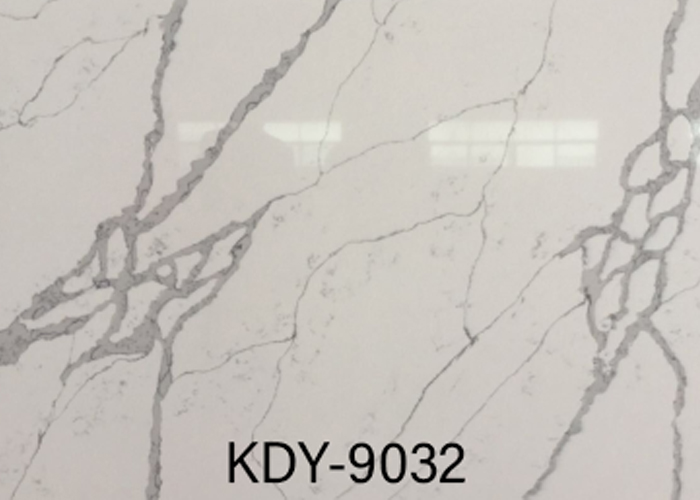

Waterproof Surface Calacatta Quartz Stone For Project

Brand KING DAYS

Product origin CHINA

Delivery time 15DAYS

Supply capacity 50000SQM/MONTH

Short Description:

Quartz stone is a high-quality green environmental protection material with soft and elegant colour and low price. It is the best choice for green buildings. It is used for kitchen countertops, bathroom countertops, window sills, bar counters, interior and exterior walls, floors, etc. It is suitable for apartments, office buildings, shopping malls, hotels, etc. Extensive requirements in different fields.

Min.Order Quantity: 100 Meter/Square Meter

Supply Ability: 50000Meter/Square Meters Per Year

Send email to us slaes@kingdaystone.com

grey quartz floor tiles 300x300

white quartz tiles 600x300

engineered quartz tile

quartz stone floor tiles

quartz tile price

white quartz bathroom tiles

quartz porcelain

quartz kitchen floor tiles

grey quartz wall tiles

black quartz wall tiles

quartz kitchen wall tiles

quartz tile flooring

floor tile

The synthesis of quartz stone plates is currently mainly controlled by a computer in a vacuum die casting machine. In the process, the curing is mostly at medium temperature. Mix the fillers of different meshes according to the required ratio, mix with the resin that has been added with the medium temperature initiator and color paste, and pump it to the hopper on the upper part of the casting machine for mixing. At the pouring port, use the console to control the moving speed and direction of the pouring port and the cutting speed to pour into the prepared mold. After the pouring is completed, the mold is sent to the bottom of the press, and then compressed by vacuum and high pressure. High temperature treatment, and finally polished to produce quartz stone plates.

Selection and mixing of raw materials 1/4 Looking for high-quality quartz minerals and other additives, quartz mineral raw materials of various particle sizes are purified by special purification equipment to remove possible impurities such as wood chips and metal fragments. Then it is transported into the raw material mixing tower, and the minerals and other additives are uniformly mixed step by step. The impurity-free raw materials and uniform mixing are the fundamental guarantee for the defect-free board.

The thickness setting ratio and the mixed raw materials enter the super-large forming machine, and the flatness and thickness of the sheet blank are accurately adjusted by the computer-induced thickness setting device, and then directly placed on the belt conveyor after forming. , Only one sheet is formed at a time.

The blank material formed by vacuum die-casting is precisely controlled by the computer in the vacuum die-casting machine. The vacuum equipment installed underground exhausts the air in the mineral voids to close to the vacuum, forming the closest accumulation of ore, mineral powder, and other additives. , To achieve a non-porous effect, the working time of each sheet is about 15 minutes. The vacuum die-casting of each super large size plate is used to ensure the material is dense and non-porous. The larger the plate size, the more complicated the process guarantee.

Details please check website www.amoygranite.com

Granite for Bathroom for Tub Surrounds,Granite for Bathroom for Wall Cladding

Granite for Bathroom for Shopping Mall,Granite for Vanity Top for Kitchen Tops,Granite for Table Tops for Kitchen Tops,Granite for Bench Top for Shower Stalls,Granite for Bench Top for Tub Surrounds,Granite for Bench Top for Wall Cladding,Granite for Bench Top for Shopping Mall,Granite for Shower Stalls for Bathroom,Granite for Shower Stalls for Bench Top,Granite for Shower Stalls for Wall Tile,Granite for Tub Surrounds for Bathroom,Granite for Tub Surrounds for Bench Top,Granite for Tub Surrounds for Wall Tile,Granite for Wall Tile for Shower Stalls,Granite for Wall Tile for Tub Surrounds,Granite for Wall Tile for Wall Cladding,Granite for Wall Tile for Shopping Mall,Granite for Wall Cladding for Bathroom ,Granite for Wall Cladding for Bench Top

Granite for Wall Cladding for Wall Tile,Granite for Floor Tile for Kitchen Tops,Granite for Shopping Mall for Bathroom ,Granite for Shopping Mall for Bench Top,Granite for Shopping Mall for Wall Tile,Giallo Granite for Flooring for Walling,Giallo Granite for Walling for Flooring,Giallo Granite for Countertop for Stair,Giallo Granite for Vanity Top for Stair,Giallo Granite for Stair for Countertop

Giallo Granite for Stair for Vanity Top,Giallo Granite for Stair for Balustrade,Giallo Granite for Window Sill for Door,Giallo Granite for Door for Window Sill,Giallo Granite for Balustrade for Stair

High Decorative Black Wooden Vein Marble,Sparkling Quartz Artificial Counter Tops,Artificial Marble Quartz Faux Stone Slab,High Decorative White Marble Vanity Tops,Waterproof Artificial Quartz Stone Slabs,Creamy White Artificial Dali Stone Plate,Classical Artificial Marble Kitchen Slab

Precast White Terrazzo Stone Floor Tile,Quartz Surface Look Terrazzo Paver Tile,Sink Cut 100% Natural Marble Vanity Tops,100% Natural Sink Cut Marble Vanity Tops,White Black Artificial Stone Counter Top,White Honed Artificial Stone Counter Top,Black White Artificial Stone Counter Top,Black Honed Artificial Stone Counter Top